- smrititarak@gmail.com

- Tarulia 2nd Lane, Krishnapur, New Town, Kolkata-700102, West Bengal

Service Details

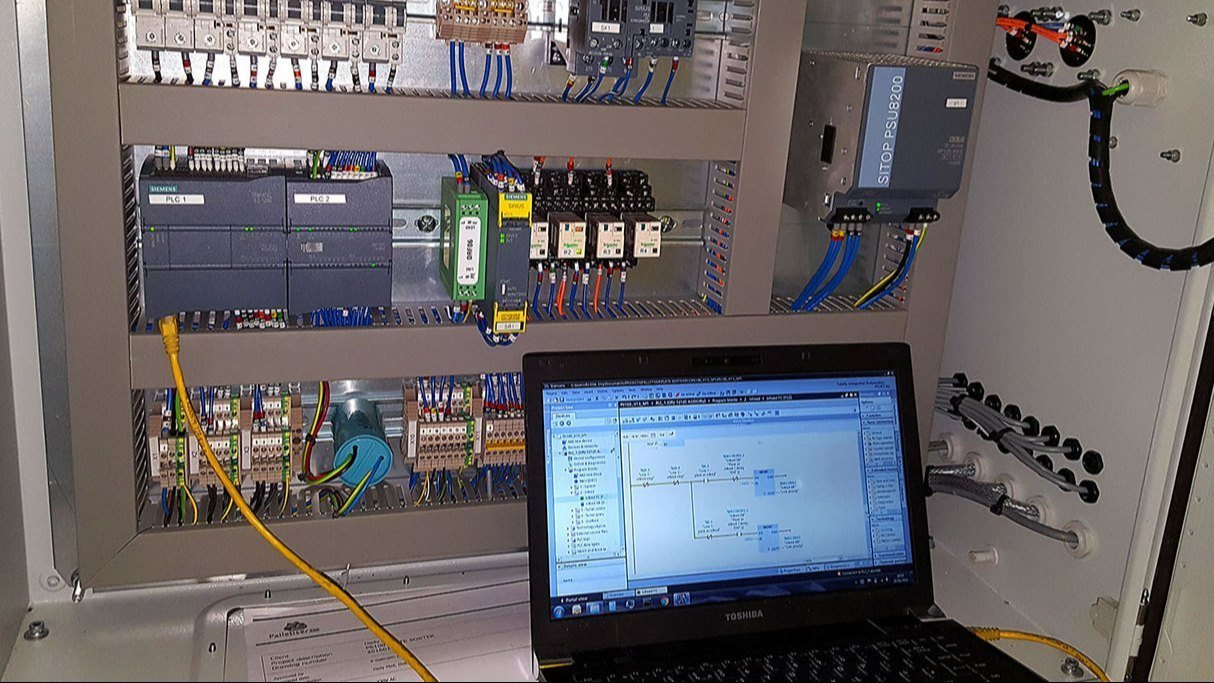

PLC Service & Programming

PLC Service & Programming – Intelligent Control for Smarter Automation

Programmable Logic Controllers (PLCs) are the brain of modern industrial automation systems, responsible for executing control logic, coordinating processes, and enabling real-time decision-making. At [Your Company Name], we specialize in PLC service and programming that ensures your automation systems operate reliably, efficiently, and in sync with your production goals.

With deep industry experience and technical expertise, we provide end-to-end PLC solutions—from initial design and development to on-site commissioning, troubleshooting, and system upgrades. Whether you are installing a new automation system, retrofitting an old process, or expanding your current operations, our PLC services are tailored to meet your specific needs.

PLC Programming

We develop custom logic programs that control a wide range of automated equipment and industrial processes. Our engineers are proficient in ladder logic, structured text, function block diagrams, and other IEC 61131-3 standard programming languages. We ensure that each program is optimized for speed, reliability, and safety, while maintaining ease of monitoring and future modification.

We work with major PLC brands including:

-

Siemens (S7-1200, S7-1500, S7-300)

-

Allen-Bradley (MicroLogix, ControlLogix, CompactLogix)

-

Delta, Mitsubishi, Schneider Electric, and others

PLC Services We Offer:

-

PLC system design and architecture planning

-

Custom logic development and programming

-

I/O mapping and signal verification

-

Integration with HMIs, SCADA, sensors, and drives

-

Communication setup (Modbus, Profibus, Ethernet/IP, etc.)

-

On-site commissioning and testing

-

PLC troubleshooting, debugging, and fault analysis

-

Firmware upgrades and logic optimization

-

Migration from legacy systems to modern PLC platforms

Industrial Applications:

Our PLC services are used across industries such as:

-

Manufacturing and assembly lines

-

Digital printing and packaging systems

-

Water and wastewater treatment plants

-

Food and beverage processing

-

Material handling and conveyor systems

-

HVAC and building automation

Why Choose Us?

-

Tailored Solutions: We create PLC programs specifically for your application needs.

-

Rapid Support: Our team is available for quick diagnostics and repairs to minimize downtime.

-

High Compatibility: Expertise in multi-brand systems and third-party device integration.

-

Full Lifecycle Support: From planning and programming to post-installation service and upgrades.